Relied On Tahoe Instrument Cluster Repair Specialists: Recovering Gauge Precision

Ultimate Resource for Advanced Auto Tool Cluster Fixing Techniques

In the realm of contemporary car maintenance, the complexities of tool collection repair work stand as an essential element of guaranteeing the ideal performance of a lorry (tahoe instrument cluster repair). As technology advances, so do the intricacies of these essential parts, requiring a detailed understanding of innovative repair work techniques. With a myriad of prospective concerns that can arise within tool collections, having a trusted source that offers extensive guidance on troubleshooting and remedying these obstacles comes to be vital. By exploring the devices needed, typical issues encountered, and step-by-step repair service methods, one can outfit themselves with the expertise required to navigate the intricate world of vehicle tool collection fixing with confidence and precision.

Relevance of Advanced Tool Cluster Fixing

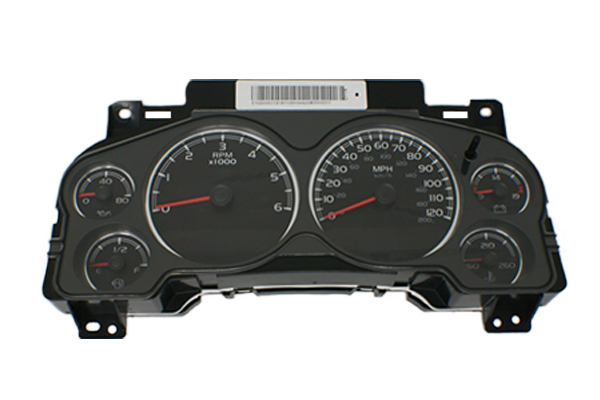

Comprehending the significance of sophisticated tool collection repair is crucial for maintaining the functionality and precision of modern car systems. The instrument cluster offers as the center of info for drivers, displaying vital information such as rate, gas degrees, engine temperature level, and cautioning indicators. With the advancement of technology, tool collections have actually advanced to include intricate electronic components and electronic display screens, making repair services a lot more complex and specialized.

Correct fixing and maintenance of the instrument collection are critical for making certain the safety and performance of the lorry. Concerns with the instrument cluster can bring about inaccurate readings, breakdowns in essential systems, and security dangers on the road. Advanced tool cluster repair service methods include detecting electronic faults, recalibrating sensing units, and reprogramming software program to restore optimum efficiency.

Tools and Devices Required

To effectively address the elaborate repair work demands of contemporary vehicle instrument clusters, a specialized collection of tools and devices is necessary. Some of the secret devices needed for sophisticated automobile tool collection fixing include precision screwdrivers, trim removal tools, soldering equipment, digital multimeters, and diagnostic scanners. By having these specialized tools and tools on hand, specialists can efficiently identify and deal with complicated issues in car tool clusters.

Common Problems and Solutions

A number of typical issues often come across in car tool clusters can be properly solved via targeted options. One common issue is faulty determines, which may result from a malfunctioning stepper motor. To resolve this, replacing the stepper motor can bring back exact scale analyses. An additional common problem is flickering or dark lights on the instrument collection (tahoe instrument cluster repair). This can frequently be attributed to a malfunctioning light bulb or inadequate connections. By replacing the light bulb or making certain protected links, the lighting concern can be easily corrected. Furthermore, a malfunctioning odometer or display screen is a constant problem. This could be as a result of a faulty display system that needs to be replaced to recover proper performance. Periodic power or complete failing of the tool cluster may stem from a blown fuse or circuitry issue. Checking and changing the fuse, in addition to examining the wiring for any problems, can help deal with these power-related problems properly. By identifying these usual concerns and using the proper solutions, auto tool cluster functionality can be recovered efficiently.

Step-by-Step Fixing Overview

A systematic technique to fixing and diagnosing car tool collection issues is important for accomplishing exact and reliable outcomes. To start the repair procedure, the very first step is to meticulously check the tool collection for any kind of noticeable damages such as burnt-out bulbs, fractured screens, or loose connections. Next, it is crucial to conduct a diagnostic check utilizing specific devices to determine any underlying electronic problems. When the trouble areas are determined, the fixing can commence by either changing faulty parts, repairing harmed circuitry, or rectifying sensors.

Tips for Preventative Maintenance

After performing an extensive analysis scan and finishing needed repair work on the car instrument read this post here cluster, executing normal preventative upkeep steps is important to make sure long-term capability and ideal efficiency of the car's important gauges and indications. To begin, it is vital to consistently check the instrument cluster for any signs of wear, such as fading screens or malfunctioning lights.

In addition, updating the software program of the tool cluster when essential can make sure compatibility with any new attributes or systems in the vehicle. It is likewise advisable to comply with the supplier's advised upkeep schedule and guidelines for the tool cluster to keep look at here its longevity. By including these preventative maintenance suggestions into your routine lorry treatment, you can help expand the lifespan and dependability of your vehicle instrument collection.

Conclusion

Finally, innovative car instrument collection repair work methods are vital for keeping the capability of contemporary vehicles. By utilizing the appropriate tools and tools, dealing with typical concerns, and adhering to a step-by-step fixing overview, specialists can successfully repair and identify instrument cluster troubles. Carrying out preventative upkeep approaches can aid lengthen the life-span of the tool collection and stop future concerns from emerging.

By discovering the tools required, common problems encountered, and step-by-step repair methodologies, one can equip themselves with the knowledge required to navigate the intricate world of auto tool cluster repair with self-confidence and precision.

A systematic approach to repairing and detecting vehicle instrument cluster issues is necessary for accomplishing precise and effective results. By following this detailed overview thoroughly, automobile technicians can efficiently repair and diagnose tool collection issues with precision and self-confidence.

In conclusion, innovative auto tool cluster repair work methods are important for keeping the capability of contemporary vehicles. By making use of the proper devices and devices, dealing with common problems, and following a step-by-step repair service guide, specialists can efficiently repair and diagnose tool cluster issues.